Medical device clean room construction |

Publisher: SOC (Jiangsu) Environmental Technology Co.,Ltd. | Hits: 256 | Published on: 2022-8-18 18:12:09 | Close |

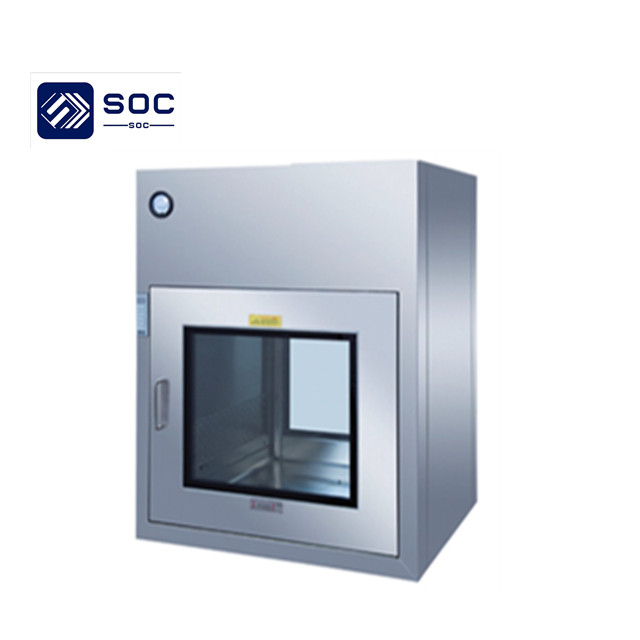

| Location requirements 1. The site selection should be considered: the surrounding natural environment and sanitation conditions are good, at least there is no air or water pollution source, and it should be far away from traffic roads, freight yards, etc. 2. Environmental requirements of the factory: the ground and roads of the factory should be level and dust-free. It is advisable to reduce the open soil area or take measures to control dust through greening. Garbage, idle items, etc. should not be stored in the open air, etc. In short, the environment of the factory area should not cause pollution to the production of sterile medical devices. 3. The overall layout of the factory area should be reasonable: it should not have adverse effects on the production area of sterile medical devices, especially the clean area. Layout requirements for clean room (area) The cleanliness level is set in accordance with the guidelines for setting the cleanliness level of the sterile medical device production environment in Appendix B of the "Standard Medical Device Production Management Specification". The following aspects should be paid attention to in the design of clean room (area) 1, according to the production process layout. The process is as short as possible, the cross-reciprocation is reduced, and the flow of people and logistics is reasonable. It must be equipped with personnel clean room (coating room, toilet, room for wearing clean work clothes and buffer room), material clean room (outsourcing room, buffer room and double-layer transfer window). Equipped with sanitary ware room, laundry room, temporary storage room, station utensil cleaning room, etc., each room is independent of each other, and the area of the clean workshop should be adapted to the production scale under the premise of ensuring the basic requirements. 2. According to the air cleanliness level, it can be written as the direction of the flow of people, from low to high; the workshop is from the inside to the outside, from high to low. 3. No cross-contamination occurs in the same clean room (area) or between adjacent clean rooms (area). 1) The production process and raw materials will not have mutual influence on the product quality; 2) There are airlock rooms or anti-pollution measures between clean rooms (areas) of different levels, and the material is conveyed through double-layer transfer windows. 4. Air purification should meet the requirements of Chapter 9 of GB 50457-2008 "Code for Design of Clean Plants in the Pharmaceutical Industry". The amount of fresh air in the clean room shall be the maximum of the following: 1) Compensate the indoor exhaust air volume and the fresh air volume required to maintain positive indoor pressure; 2) No one indoor fresh air should be less than 40m3/h. 5. The per capita area of the clean room should be no less than 4mm (except corridors, equipment and other items) to ensure a safe operating area. 6. In the case of in vitro diagnostic reagents, it should meet the requirements of the "Implementation Rules for the Production of In vitro Diagnostic Reagents (Trial)". Among them, the processing operations of negative and positive serum, plasmids or blood products should be carried out in an environment of at least 10,000 grades, and relative negative pressure should be maintained with adjacent areas, and should meet the protection requirements. 7. The direction of the return air, supply air and water pipes should be marked. |