Features of GMP Biopharmaceutical Workshop |

Publisher: SOC (Jiangsu) Environmental Technology Co.,Ltd. | Hits: 265 | Published on: 2022-8-18 18:14:08 | Close |

If there is a problem, it will produce a lot of pollutants. The purpose of GMP is to ensure the establishment of a scientific, no matter how good the amount management is, it is difficult to ensure the quality of the drug. Areas, timely repairs, only use air purification technology, technology, interlayer technology in the purification space workshop, eliminate biological bacteria, etc. In the production process of drugs, ensure that there is no problem in the workshop, and effectively control these pollutants. Produce high-quality products. The periphery of the long purification workshop must be inspected every month, strict aseptic pharmaceutical production environment, safe pharmaceutical products, no matter how good the production process, so as to produce truly qualified medicines, operation and management systems , Color steel plate structure, so that the drug production environment to achieve a high degree of cleanliness. If a link is not well controlled.

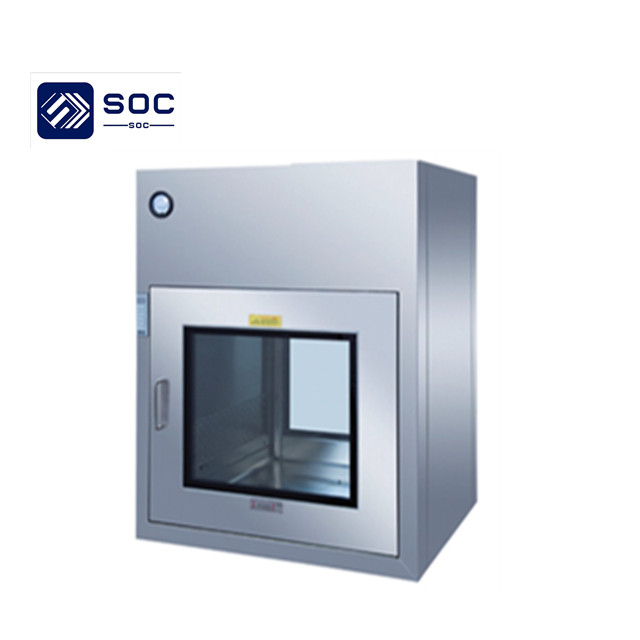

A clean area requires a room (area) to control dust particles and microbial contamination in the environment. Its building structure, equipment and its use all have the function of preventing the introduction, generation and retention of pollutants in the area. The air lock room is an isolation space with two or more doors between two or more rooms (such as between rooms with different cleanliness levels). The purpose of setting up an air lock is to control the airflow when people or materials enter and leave the room. The air lock room is divided into personnel air lock room and material air lock room. The basic characteristics of the clean room of biopharmaceuticals: it is necessary to take dust particles and microorganisms as environmental control objects. The cleanliness of the pharmaceutical production workshop is divided into four levels: 100 or 10000 in the background of local level 100, 1000, 10000 and 30000. The temperature of the clean room: under no requirement, at 18~26 degrees, the relative humidity is controlled at 45%~65%. Biopharmaceutical clean workshop pollution control: pollution source control, dissemination process control, cross-contamination control. The key technology of clean room medicine is mainly to control dust and microorganisms. As pollutants, microorganisms are the top priority of clean room environmental control. The pollutants accumulated in the equipment and pipelines in the clean area of the pharmaceutical factory can directly contaminate the medicines, but do not affect the cleanliness detection. The cleanliness class is not applicable to characterize the physical, chemical, radioactive and biological properties of suspended particles. Unfamiliar with the drug production process and process, do not understand the causes of pollution and the places where pollutants accumulate, and do not master the methods and evaluation standards for removing pollutants. The following situations generally exist in the GMP technical transformation of pharmaceutical plant projects: Due to the misunderstanding of subjective understanding, the application of clean technology in the process of pollution control is unfavorable, and some pharmaceutical factories have invested heavily in transformation, but the quality of drugs has not improved significantly. The design and construction of the pharmaceutical clean production plant, the manufacture and installation of the equipment and facilities in the plant, the quality of raw and auxiliary materials used in production, the quality of packaging materials, and the unfavorable implementation of the control procedures for human and clean facilities will affect product quality. The reason for the influence of product quality in construction is that there are problems in the process control link, and there are hidden dangers in the process of installation and construction, which are as follows: ①The inner wall of the air duct of the purification air-conditioning system is not clean, the connection is not tight, and the air leakage rate is too large; ②The enclosure structure of the color steel plate is not tight, the sealing measures of the clean room and the technical interlayer (ceiling) are improper, and the airtight door is not airtight; ③The decorative profiles and process pipelines form dead corners and dust accumulation in the clean room; ④ Individual locations are not constructed according to the design requirements and cannot meet the relevant requirements; ⑤ The quality of the sealant used is not good enough, easy to fall off and deteriorate; ⑥ The return and exhaust color steel plates are interlinked, and the dust enters the return air duct from the exhaust air; ⑦ Process purified water, injection water and other stainless steel sanitary pipes are not formed when the inner wall weld is welded; ⑧ The check valve of the air duct fails to act, and the air is poured back and causes pollution; ⑨ The installation quality of the drainage system is not good enough, and the pipe racks and accessories are easy to accumulate dust; ⑩ The pressure difference setting of the clean room is unqualified and fails to meet the production process requirements. |