Construction method of purification project |

Publisher: SOC (Jiangsu) Environmental Technology Co.,Ltd. | Hits: 262 | Published on: 2022-8-18 18:19:53 | Close |

In developed countries, purification engineering is widely used in hospitals, laboratories, factories, schools, substation rooms, computer rooms. Some residences with higher requirements on the environment also have applications. In China, due to the accelerated pace of modernization, purification equipment is generally installed in the operating rooms of domestic top three hospitals. A thousand-level purification operating room is necessary for brain surgery. Due to the high purification environment, many hospitals in China can now perform operations that were not dared or could not be performed before. In electronic factories, tens of millions of electronic components can be integrated in a small volume due to the high purification environment. Our commonly used electronic products such as mobile phones must have a good purification environment before they can be produced. It will become more and more refined, and the function will become more and more powerful.

In a clean environment, our computer room will not malfunction due to dust. In the laboratory, our experiments are not disturbed by dust. At the factory, we can produce assured food with a long shelf life. Wide application of purifying the environment, benefiting society and mankind.

Purification standard The purification project generally adopts the US Federal 209 standard. Specifically, it is divided into one hundred thousand, ten thousand, thousand, one hundred, ten, and one. 10,000-level applications are the most common. In a 100-level purification environment, it can meet the most advanced experimental requirements in China, can produce precision electronic components, and can perform complex craniotomy operations. But the construction is more difficult and the cost is higher. Let's take a thousand-level clean room as an example to talk about the construction method and specific process design requirements. Purification pipeline requirements The clean room determines the purification level according to the purpose, and adjusts the temperature, humidity, and ventilation times of the clean room as needed. The temperature can be adjusted by stainless steel pipes or by special air conditioners for clean rooms. The humidity is adjusted by special equipment according to the specific process requirements. According to different purification requirements, the construction materials and construction techniques we use are different. Class 1000 clean rooms must be insulated with stainless steel plates. There should be no slight deformation at the joints of the steel plates. The isolation steel plate of the thousand-level clean room currently needs to be purchased from Beijing, Shanghai and other places. Purification pipes can be stainless steel pipes and galvanized pipes. The outside of the pipe should be insulated. Before pipeline construction, it is very important to clean the inside of the pipeline, and it is not necessary to wait until all the pipelines are installed to do the cleaning. This is the key to construction. Many projects cannot be accepted and qualified, which is related to this and should be paid special attention. The design of the duct is related to the size of the clean room, the size of the air supply, and the purification requirements. The size and air volume of the purification air conditioner can be adjusted according to the needs in the specific construction process. Due to different environments and geographical locations, construction techniques are also different. To be designed according to actual requirements. For example: the same 900 square meters of purification plant, there are 50 workers and 100 workers need to adjust the ventilation duct design. Consider it comprehensively when designing. According to experience, specific environment, adjust the design. Purification Filtration Requirements The ventilation duct generally adopts three-stage filtration, namely ordinary filter device, medium-efficiency filter device, and high-efficiency filter device. The quality of the filter needs to be checked carefully. The filter of poor quality is used for a short time and the filtering effect is not good. In particular, the wind resistance is too large, resulting in a small air volume. According to my investigation, the high-efficiency filter of the thousand-level clean room needs to be purchased in Shanghai. The reconnection part of the ventilation duct should use a good quality sealing ring. Use sealant to make up for the quality problem of the sealing ring. If the time is a little longer, there will be problems with the pipe sealing, which is very troublesome to solve. will cause unexpected losses. If there is a problem with the quality of the air supply duct, it is equivalent to overturning the entire project. The quality of the purification project has problems, most of which are problems with the installation of the pipeline. Re-applying the sealant can only solve the problem temporarily. Some user units have frequent replacement of high-efficiency filters, usually because the air supply pipeline is faulty, so the installation of purification pipelines must be careful. The project supervisor cannot leave for a minute.

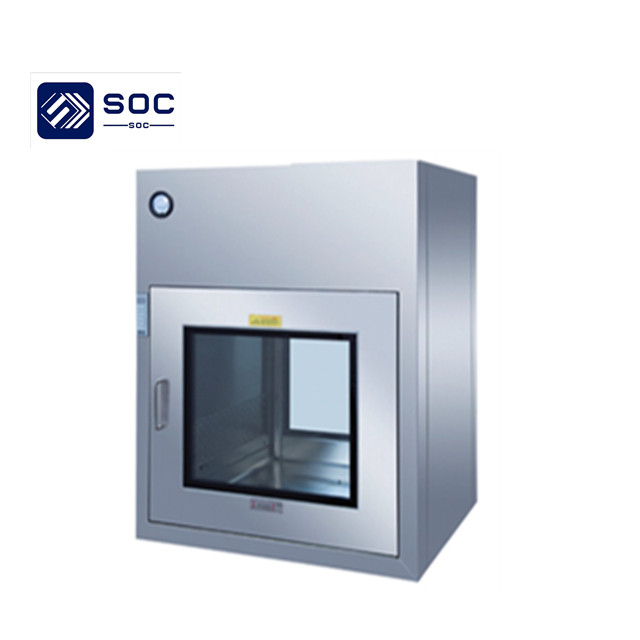

Purification fan selection The number of fans installed in the clean room is determined according to the usage time. If it is used 24 hours a day, at least two fans should be installed. If you use it for eight hours a day, you can install less than two fans. If it is used intermittently, install a fan. The model and size of the fan are determined according to the area of the clean room. Air shower installation The air shower is equivalent to the first barrier of the clean room, and the specific model is determined by the number of people passing through per unit time. When installing the air shower, the joints should be tightly sealed. There is a problem with the first barrier, and no amount of subsequent barrier protection will work. The first line of defense must not have a single problem, and you must be careful when installing. The glass window of the clean room is also a difficult construction point, which is prone to problems and needs special attention. Generally, double-layer vacuum glass is used. During installation, the periphery is sealed with high-quality sealant, and the glass window is installed in the sealing groove. Cleanroom ceiling requirements The ceiling of the clean room has a certain height from the ceiling. The general height is about 1.8 meters, which is convenient for maintenance and installation of lighting equipment. The ceiling of the clean room is the largest part of the clean room installation, and it is also the most difficult part to construct. No matter how big the ceiling of the clean room is, it should look as a whole after installation, with no seams and the same level. The ceiling must be hoisted firmly and cannot be moved due to temperature changes. In most cases, the clean room has positive air pressure, that is, the indoor air pressure is higher than the outdoor air pressure. This will produce a certain pressure on the ceiling of the larger clean room, causing tiny gaps in the ceiling, which will affect the purification effect. To solve this problem, the perimeter of all joints of the roof must be treated with sealant during construction. The sealant must use a mildew-resistant sealant.

|