What are the commonly used purification equipment |

Publisher: SOC (Jiangsu) Environmental Technology Co.,Ltd. | Hits: 248 | Published on: 2022-8-18 18:25:57 | Close |

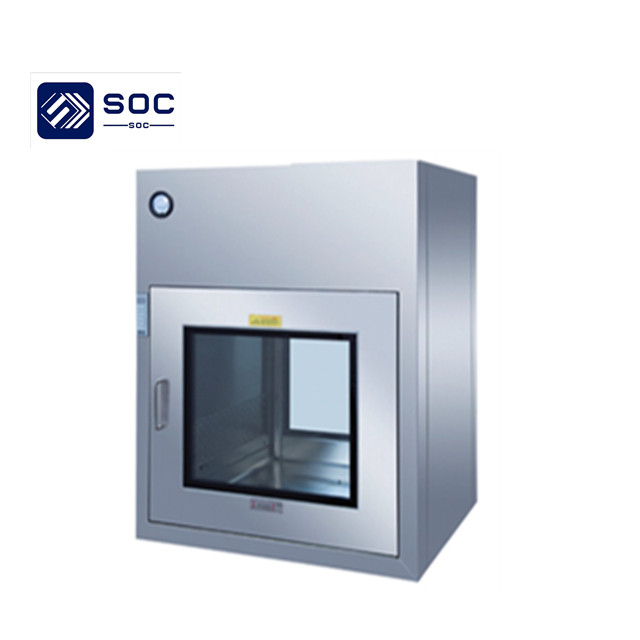

| 1> Air shower room: The air shower room is a necessary purification equipment for personnel to enter the clean and dust-free workshop. It has strong versatility and can be used with all clean rooms and clean workshops. When workers enter the workshop, they must pass this equipment and use strong and clean air. The rotatable nozzles are sprayed on people from all directions, effectively and quickly remove dust, hair, hair flakes and other debris attached to the clothes, which can reduce the pollution caused by people entering and leaving the clean room. The two doors of the air shower room are electronically interlocked, which can also function as an air lock, preventing external pollution and unpurified air from entering the clean area. Prevent staff from bringing hair, dust and bacteria into the workshop, meet the strict dust-free purification standards of the workplace, and produce high-quality products. 2> Transfer window: The transfer window is divided into standard transfer window and air shower transfer window. The standard transfer window is mainly used for the transfer of items between the clean room and the non-clean room to reduce the number of door openings. It is the best purification equipment to effectively reduce the cross-contamination between the clean room and the non-clean room. The transmission windows and doors are all double-door interlocking, (that is, only one door can be opened at a time, and after one door is opened, the other door cannot be opened). According to the different materials of the box, the transfer window can be divided into: stainless steel transfer window, outer steel plate inner stainless steel transfer window, etc. The transmission window can also be equipped with a germicidal lamp (8W), a walkie-talkie, etc. 3> Air shower transfer window: The air shower transfer window is an auxiliary equipment of the clean room. In order to reduce a large number of dust particles caused by the entry and exit of the goods, the clean air flow filtered by the high-efficiency filter in the air shower transfer window is sprayed onto the goods from all directions by the rotatable nozzles. , effectively and quickly remove dust particles, and the removed dust particles are filtered by the primary and high-efficiency filters and recirculated to the air shower area. In order to achieve the best effect of blowing, the wind speed of the nozzle outlet can reach more than 20s. 1.According to the structure, the air shower transfer window can not be divided into: air shower transfer window and floor-to-ceiling air shower transfer window; 2. According to the different materials of the box, the air shower transfer window can be divided into: stainless steel air shower transfer window, stainless steel air shower transfer window in the outer steel plate, etc. (the inner tank of the transfer window is made of sand-surface stainless steel); 3. The transfer window can be divided into: electronic interlocking air shower transfer window and mechanical interlocking air shower transfer window according to different interlocking methods. 4> FFU fan filter unit: FFU English full name (Fan Filter Unit) has the characteristics of modular connection. There are primary and high-efficiency filters respectively. The working principle is: the fan sucks the air from the top of the FFU and filters it through the primary and high-efficiency filters, and the filtered clean air is evenly sent out through the air outlet surface at an average wind speed of 0.45m/s. The FFU fan filter unit adopts a lightweight structure design, which can be installed in accordance with the Grid system of various manufacturers, and the structural size design of the FFU can be changed according to the Grid system. The internal diffuser plate is installed, the wind pressure spreads evenly, and the wind speed on the air outlet surface is average and stable. The metal structure downwind liner will never age. Eliminate secondary pollution, smooth surface, low wind resistance, excellent sound insulation effect. Special air inlet duct design reduces pressure loss and noise. High motor efficiency and low system current consumption save energy costs. The single-phase motor provides three-stage speed regulation, which can increase or decrease the wind speed and volume according to the actual situation. According to customer requirements, it can be used as a single unit or in series to form multiple 100-level production lines. Control methods such as electronic board speed regulation, gear speed regulation, and computer centralized control can be selected. It has the characteristics of energy saving, stable operation, low noise, and digital adjustment. Widely used in electronics, optics, national defense, laboratories, hospitals and other places where air cleanliness is required, and can also be assembled into static 1-300,000-level static The clean work shed is very suitable for the construction of a small area of clean area, which can save money and time in building a clean room. 1.FFU purification level: static level 100; 2. FFU wind speed: 0.3/0.35/0.4/0.45/0.5m/s, FFU noise ≤46dB, FFU power supply is 220V, 50Hz. ; 3. The FFU adopts a high-efficiency filter without partitions, and the FFU filtration efficiency is 99.99%, ensuring the purification level; 4. The whole FFU is made of high-quality galvanized sheet; 5. FFU stepless speed regulation design, stable speed regulation performance, FFU can still ensure the constant air volume under the state of final resistance of the high-efficiency filter; 6. FFU adopts high-efficiency centrifugal fan, which has long service life, low noise, maintenance-free and small vibration; 7. FFU is especially suitable for assembling into ultra-clean production line. It can be arranged as a single FFU according to the needs of the process, or multiple FFUs can be used to form a 100-level assembly line. 5>Laminar flow hood: The laminar flow hood is mainly composed of a box, a fan, a high-efficiency air filter, a coarse-efficiency filter, a porous plate, and a controller. After the laminar flow hood passes the air through the high-efficiency filter at a certain speed, a uniform flow layer is formed, so that the clean air flows in a vertical unidirectional flow, thereby ensuring the high cleanliness required by the process in the working area. It is an air purification unit that can provide a local clean environment. It can be flexibly installed above the process points that require high cleanliness. The clean laminar flow hood can be used alone or combined into a strip-shaped clean area. The laminar flow hood can be suspended or supported on the ground, and has a compact structure and is easy to use. 1. Laminar flow hood purification level: static level 100, dust with a particle size of ≥0.5m in the working area ≤3.5 particles/liter (FS209E100 level); 2. The average wind speed of the laminar flow hood is 0.3-0.5m/s, the noise is ≤64dB, and the power supply is 220V, 50Hz. ; 3. The laminar flow hood adopts a high-efficiency filter without a partition, and the filtration efficiency is: 99.99%, ensuring the purification level; 4. The laminar flow hood is made of high-quality cold plate baking paint, aluminum plate or stainless steel plate as a whole; 5. Laminar flow hood control mode: stepless speed regulation design or electronic board speed regulation, the speed regulation performance is stable, and the laminar flow hood can still ensure the constant air volume under the state of the final resistance of the high-efficiency filter; 6. The laminar flow hood adopts high-efficiency centrifugal fan, which has long service life, low noise, maintenance-free and low vibration; 7. The laminar flow hood is especially suitable for assembling into an ultra-clean production line. It can be arranged as a single laminar flow hood according to the needs of the process, or multiple laminar flow hoods can be used to form a 100-level assembly line. 6> Clean workbench: The clean workbench is divided into two types: vertical flow workbench and horizontal flow workbench. The clean workbench is one of the preferred purification equipment to improve process conditions and ensure cleanliness. It is widely used in local production areas requiring high cleanliness, such as : laboratories, biopharmaceuticals, hospitals, LED optoelectronics, circuit boards, microelectronics, hard disk manufacturing, food processing and other fields. Features of clean workbench: 1. The clean workbench adopts ultra-thin filter without partition, and the filtration efficiency is static level 100. 2. The medical workbench is equipped with a high-efficiency centrifugal fan, which has long life, low noise, maintenance-free and low vibration. 3. The ultra-clean workbench adopts an adjustable air supply system, and the knob-type stepless adjustment of wind speed and LED control switch can be selected. Ensure cleanliness. 5. The static 100-level workbench can be used alone according to the process requirements, or multiple sets can be combined into a 100-level ultra-clean production line. 6. The clean workbench can be equipped with a differential pressure gauge, which clearly indicates the differential pressure on both sides of the high-efficiency filter, so as to remind the replacement of the high-efficiency filter. 7. The ultra-clean workbench has a variety of specifications, which can be customized according to production requirements. 7> Efficient air outlet: The high-efficiency air outlet is composed of a static pressure box, a diffuser plate, a high-efficiency filter and a flange; the interface with the air duct has two types: side connection and top connection. The surface of the box is made of cold-rolled steel plate by multi-layer pickling electrostatic spraying, and the air outlets have good airflow to ensure the effect of purification; Critical equipment for decontamination requirements. Optional functions of the high-efficiency air outlet: 1. The high-efficiency air outlet can choose side air supply and top air supply according to different requirements of customers. Flange can also choose square or round mouth, which is convenient for connecting the air duct. 2. The high-efficiency air outlet static pressure box can be selected: cold-rolled steel plate baking paint, 201 stainless steel, 304 stainless steel. 3. The high-efficiency air outlet flange can be selected: square or round mouth, which is convenient for the needs of the air duct. 4.High-efficiency air outlet diffuser can be selected: cold-rolled steel plate baking paint, 201 stainless steel, 304 stainless steel 5. The high-efficiency filter of the high-efficiency air outlet is available with or without a partition. 6. Optional accessories for high-efficiency air outlet: thermal insulation layer, manual air volume control valve, thermal insulation cotton, DOP test port. |